Understanding the Role of Injection Robots in Modern Manufacturing

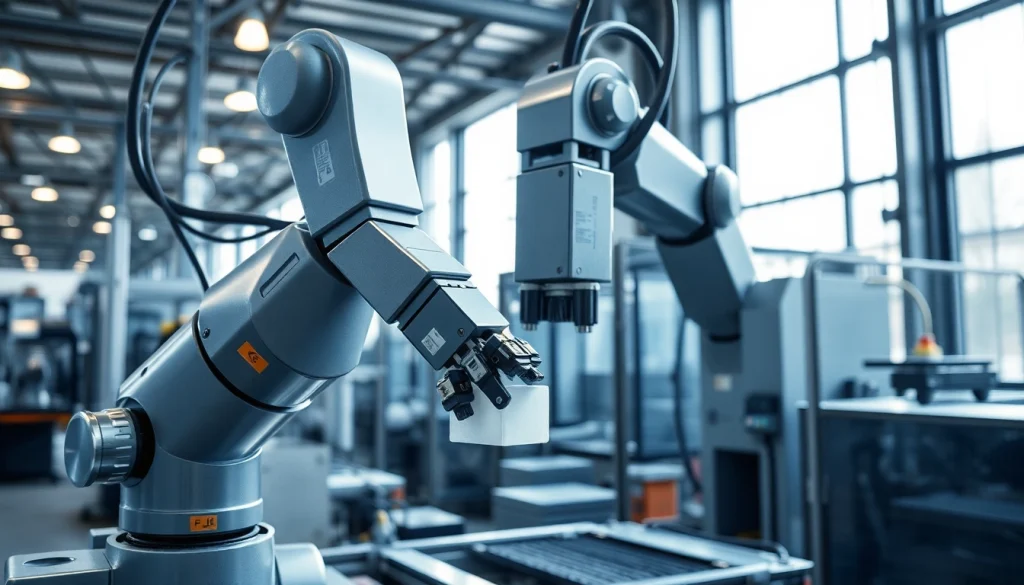

In the fast-evolving landscape of industrial manufacturing, Injection Robots have emerged as pivotal tools that enhance efficiency, precision, and productivity. These automated systems are not merely a trend; they represent a fundamental shift toward intelligent manufacturing. By incorporating advanced robotics into injection molding processes, businesses can achieve unprecedented levels of performance and reliability.

What is an Injection Robot?

An injection robot is a specialized robotic system designed for handling tasks associated with injection molding processes. This includes the automated removal of molded parts, sprue picking, and assembly operations. Typically featuring advanced servo motors and sophisticated programming, these robots are capable of performing high-speed operations with accuracy that surpasses manual labor. They are integral to modern factories, integrating seamlessly with injection molding machines to facilitate rapid production cycles.

Benefits of Using Injection Robots

The integration of injection robots into manufacturing operations provides numerous benefits:

- Increased Efficiency: Robots can operate continuously without the fatigue that affects human workers, leading to reduced cycle times and increased output.

- Enhanced Precision: High-level accuracy in part handling minimizes defects and waste, ensuring high-quality production.

- Cost-Effectiveness: Although the initial investment is significant, the long-term savings in labor costs and increased throughput can yield high returns.

- Improved Safety: By automating dangerous or repetitive tasks, robots enhance workplace safety and reduce injury risks for human employees.

- Flexibility: Modern injection robots can be reprogrammed and adapted to accommodate various production needs, making them versatile solutions for manufacturers.

Common Applications in the Industry

Injection robots are utilized across various sectors, including:

- Automotive: For the production of components like dashboards, panels, and tire molds.

- Consumer Goods: In the creation of plastic containers, toys, and household items.

- Medical Devices: For manufacturing critical components that require precision and reliability.

- Aerospace: In producing lightweight and durable parts that meet stringent safety standards.

Choosing the Right Injection Robot for Your Operations

Selecting the appropriate injection robot involves carefully considering various factors critical to your unique operational needs. The right choice can significantly impact production efficiency and product quality.

Factors to Consider When Selecting an Injection Robot

Key aspects to evaluate include:

- Payload Capacity: Determine the maximum weight the robot can handle to suit your specific components.

- Speed and Cycle Time: Assess the robot’s speed to ensure it meets production demands without compromising quality.

- Compatibility: Ensure the robot integrates well with existing injection molding machines and software.

- Programming and User Interface: Opt for systems that offer intuitive programming for ease of use and quick reconfiguration.

- Maintenance Requirements: Consider both scheduled maintenance and the availability of technical support from the manufacturer.

Comparing Different Models and Brands

With numerous brands and models available, comparative analysis is essential. Focus on:

- Performance metrics such as speed and accuracy.

- Cost of ownership, including initial investment and ongoing maintenance expenses.

- Manufacturer reputation and post-sale support.

- Innovative features like advanced sensors and artificial intelligence capabilities.

Cost Considerations and Budgeting for Injection Robots

The cost of injection robots can vary widely based on specifications and functionalities. Budgeting should encompass:

- Initial Purchase Cost: The upfront expense of the robot and any necessary peripherals.

- Installation and Integration Costs: Expenses associated with integrating the robot into existing systems.

- Operational Costs: Ongoing costs related to power consumption, maintenance, and repairs.

- Software Licensing Fees: If applicable, consider the costs associated with any software needed for programming and operation.

Integrating Injection Robots into Your Production Line

A systematic approach to integration is essential for achieving the desired outcomes with injection robotics. This involves careful planning and execution.

Step-by-Step Guide to Implementation

Follow these steps for a successful integration:

- Assessment: Evaluate current processes to identify tasks suitable for automation.

- Selection: Choose an injection robot that meets your operational needs.

- Installation: Set up the robot and connect it to your injection molding machinery.

- Programming: Configure the robot’s software for specific tasks and workflows.

- Testing: Conduct comprehensive testing to ensure functionality and efficiency.

- Training: Provide staff training on operating and maintaining the new system.

Common Challenges and How to Overcome Them

Integration can present challenges such as:

- Resistance to Change: Employees may be hesitant to adapt to new technologies. Address this through training and clear communication about benefits.

- Technical Issues: Ensure reliable technical support and thorough pre-installation assessments to mitigate common technical problems.

- Budget Constraints: Explore financing options or phased implementation to manage costs effectively.

Case Studies: Successful Integrations

Numerous companies have seen significant improvements through successful robot integration:

- Automotive Manufacturer: A leading manufacturer reduced cycle time by 30% through the implementation of a multi-axis injection robot.

- Consumer Electronics Company: Automated their assembly lines, increasing output by 40% while maintaining high standards of quality.

- MedTech Firm: Utilized injection robots to manufacture intricate medical devices, resulting in a 50% reduction in production errors.

Maximizing Efficiency with Injection Robots

To fully leverage the advantages of injection robots, organizations must adopt best practices and continuously seek optimization opportunities.

Best Practices for Operation and Maintenance

Maintain efficiency by adhering to these best practices:

- Regular Maintenance: Schedule consistent maintenance checks to prevent breakdowns and prolong robot lifespan.

- Continuous Training: Offer ongoing training to ensure staff is updated on new features and operational best practices.

- Utilize Analytics: Implement data analytics tools to monitor performance and identify areas for improvement.

Real-Time Monitoring and Performance Metrics

Utilizing real-time monitoring systems can enhance operational oversight. Key performance metrics to track include:

- Production Rate: Monitor the number of parts produced within a specific timeframe.

- Downtime: Analyze factors contributing to unplanned shutdowns and implement corrective actions.

- Quality Control: Measure defect rates to maintain product quality standards.

Innovative Techniques for Optimization

Explore innovative strategies to enhance robot performance:

- Adaptive Learning: Incorporate machine learning algorithms to allow robots to continuously improve their operations.

- Collaborative Robots (Cobots): Consider integrating cobots that work alongside human operators for flexible task handling.

- Data-Driven Insights: Leverage big data analysis for predictive maintenance and to optimize production schedules.

The Future of Injection Robots in Manufacturing

As technology evolves, the future of injection robots looks promising, with emerging trends that will redefine manufacturing standards.

Emerging Trends and Technologies for 2025

Looking ahead, key technologies include:

- Artificial Intelligence: Enhanced AI capabilities will allow robots to analyze data and adapt workflows dynamically.

- Internet of Things (IoT): More connected devices will facilitate better communication between machines, promoting efficiency.

- Augmented Reality (AR): AR applications could assist in training and maintenance, providing real-time guidance for operators.

How Automation Will Shape the Industry

Automation will increasingly dominate manufacturing, leading to:

- Reduced Labor Costs: A shift towards automated processes will lower dependence on manual labor, decreasing costs.

- Enhanced Production Flexibility: Facilities will become more agile, adapting quickly to market demands and changes in production runs.

- Sustainability Focus: Automation will enable more efficient use of resources, contributing to environmentally friendly practices.

Expert Predictions and Insights

Industry experts predict that by 2025, robotics will become ubiquitous in manufacturing, with advanced capabilities that enhance operational efficiency and product quality. Continuous innovation will foster a competitive edge for early adopters, paving the way for a new era of intelligent manufacturing solutions.